Solar Chemicals

Solar Chemicals

Renewable resources, such as solar energy, are playing an increasingly important role in power supplies throughout the globe

Photovoltaics (PV) and concentrated solar power (CSP) plants are used to capture the sun’s energy. PV technology has become an integral part of the worldwide energy mix, and will only grow in importance as time goes on. The standards for this technology are very high. And BASF is helping to advance PV even further – with reliable, intelligent and innovative chemical solutions.

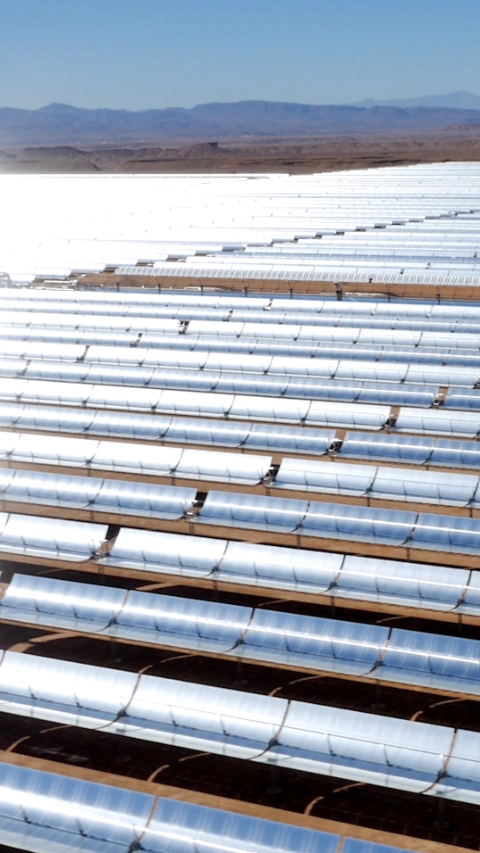

CSP technology, meanwhile, concentrates solar radiation to heat up a fluid, and uses this heat to generate electricity. This technology makes it easy to store thermal energy – enabling the production of energy even when the sun is not shining. BASF contributes to this technology through the production and supply of salts used for heat storage and heat transfer. Additionally, BASF offers consultancy services and engineering solutions tailored to multiple stages of plant development and operation.

BASF salts and services for concentrated solar power industry

Extensive experience and cutting-edge innovation: when you join forces with BASF, you get the best of both worlds. Not only are you are guaranteed exceptionally pure products for concentrated solar power (CSP) heat transfer and thermal energy storage processes. You can also tap into a wealth of expertise in the form of tailor-made consulting services, helping you maximize efficiency at your facility. Whether you are new to the market or an experienced player seeking an extra edge, BASF is the partner of choice.