Why is this topic important?

Polyamides and Intermediates

Mechanical recycling of polyamide-containing multilayer structures

Recycling of polyethylene/polyamide composite packaging is already state-of-the-art

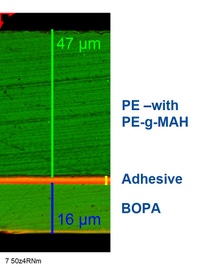

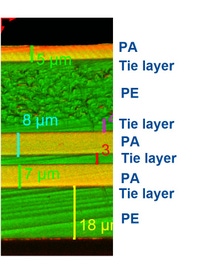

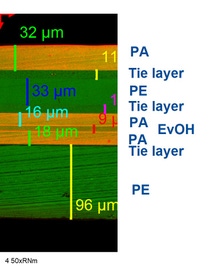

Multi-layer packaging combines the best properties of different materials and thus achieves the best product protection with minimal material use. Polyethylene/polyamide packaging is used in applications with high mechanical and thermal demands (such as sausage, cheese or meat packaging).

Cyclos HTP certificates

Currently, polyamide-containing packaging is still declared as non-recyclable in "Design-for-Recycling" guidelines of various organizations, although the studies come to a different conclusion: The independent institute cyclos-HTP, together with BASF, has investigated the recyclability of various polyamide-containing packaging structures in detail.

Conclusion: all structures are compatible in the relevant PE flexible waste stream fractions (plastic films/flexible polyethylene packaging), in which most polyamide-containing polyethylene films are already recycled today.

Recyclability of coextruded polyethylene/polyamide films

Due to the currently very pronounced focus on the mechanical recycling of packaging waste from households and here on the so-called "monomaterials" desired by the recycling industry and politics, the advantages of polyamides for high-performance and flexible packaging are being pushed into the background. Certain criteria, such as the reduction of the used plastic due to lower material thicknesses ("downgauging"), the associated reduction in plastic waste volumes or the improved utilization of foodstuffs due to extended shelf life in barrier packaging with polyamide, are not adequately taken into account. Yet these criteria play an important role when it comes to supplying food to a continuously growing world population and reducing packaging waste and food wastage.

The currently realized update concerning compatibility of coextruded PE/PA multilayer films in the category “LDPE and films” of “Minimum standard for determining the recyclability of packaging subject to system participation pursuant to section 21 (3) VerpackG” of ZSVR in Germany is a first and extremely important step to consider the advantages of PA containing packaging structures as well as the latest state-of-technology in terms of recyclability of Polyamides into legislation basics. Due to the fact, that there are a lot of things to do, especially in view of the still ongoing finalization of EU legislation, we as BASF will continue to work and argue for a serious categorization of Polyamides in flexible packaging structures.

“Film-to-film” approach for PE/PA waste blends is a real recycling option including manufacturing of “new” monolayer films:

.jpg)

.jpg)