Ultramid® (PA) film

- Good mechanical properties

- Optical properties

- Heat resistance

- Flavor, aroma and chemical barrier

- Oxygen barrier

- Thermoformability

Monomers

Due to its special property profiles Ultramid® based mono- or multilayer constructions may also be used in industrial applications such as release films for sheet molding compound (SMC), prepregs or roof underfelt sheeting.

Ultramid® is well suited for the production of biaxially oriented (BOPA) film which provides high stiffness, puncture resistance, aroma- and oxygen barrier and transparency.

The importance of Ultramid® film in the packaging sector is based on its high strength, excellent thermoformability, high heat resistance including resistance to sterilizing temperatures and the very good barrier properties to gases, particularly oxygen, and flavors and aromas.

The combination of Ultramid® with polyethylene produces an ideal flexible material for vacuum packing oxygen-sensitive food such as sausage, ham, cheese, fish, peanuts etc., the main application for Ultramid® film.

The good thermoformability of Ultramid® film ensures particularly well-shaped, promotional and thus cost-effective packaging.

Ultramid® is very well suited for the production of biaxially oriented (BOPA) film because it provides high stiffness, puncture resistance, barrier and transparency.

PA artificial sausage casing is characterized by a high oxygen barrier and good printing properties and gauge consistency.

Due to its special property profiles, Ultramid® and Ultramid/PE composite film has interesting applications in the chemical/technical field, such as release film for SMC (sheet molding compound), prepegs and moisture-permeable roof underfelt sheeting.

Selection of the suitable Ultramid® grade is determined by the film properties required, processing and, in coextruded film, on the viscosity behavior of the other polymers in the composite. Ultramid® B36 LN (polyamide 6) is often combined with PE-LD or PE-LLD with a melt index of approx. 3.0- 4.0 g/10 min, whereas Ultramid® B40 L or B40 LN is combined with polyethylene with a melt index of approx. 0.8-1.0 g/10 min.

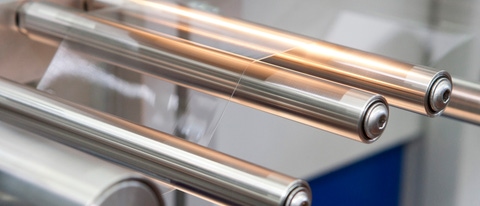

Ultramid® can be processed with standard extrusion equipment. We recommend extruder screws with an L/D ratio of 24-30 and a constant pitch of 1 D. The compression ratio should be between 3:1 and 3.5:1 (Fig. 1). The flight depths themselves depend on the screw diameter D and on the melt viscosity. Barrier screws are used especially for a constant output. Gentler melting and constant transport of the melt in a narrow output range are possible here. The screw clearance (radial clearance between the screw and the barrel) should be 0.1-0.2 mm to minimize leakage. Shear sections at 22-25 D are recommended for screws with a diameter of 90-150 mm.

Biaxially oriented (BOPA) film may be manufactured from Ultramid® B resins by rapid cooling of film and subsequent simultaneous or sequential stretching in machine and transverse direction. Cast (tenter frame) or blown (double bubble) technology may be applied. Stretch ratio will usually be between 2.7 and 3.2 (both machine and transverse direction).

Artificial sausage casing may be manufactured from Ultramid® as both conventional as well as biaxially oriented shrinkable blown film. PA 6 is highly suited for oriented, shrinkable film. Biaxially oriented casing is frequently coextruded with polyolefins in order to achieve the required water vapor barrier in a multilayer film application.

Flat film (extruded film) and tubular film (blown film) which are used primarily for food packaging, mainly in combination with polyethylene, are extruded from medium to high viscosity Ultramid® B (PA 6) and C (PA 6/66) grades.

Multilayer blown film from Ultramid® B or C resins, polyolefins and suitable adhesive materials may be coxetruded utilizing commercially available equipment as used for manufacturing of polyethylene blown film. Especially in the case of a non-symmetric layer structure (e. g. PE/tie/PA/ Ultramid® C), copolyamides are preferred to produce highly thermoformable and flexible multilayer film with high transparency and low curl. The curl may be further reduced by humidification of the film by a hot-water bath. Monolayer blown film may also be produced using Ultramid® B grades.

The die gap should be approx. 2.0-2.5 mm (multilayer film) or 0.5-1.5 mm (monolayer film). The extruded film is cooled with air, a take-off speed of more than 30 m/min (100 ft/min) is achievable. Typical blow-up ratio (die diameter / tube diameter) lies in the range of 1:3.0.

The tube should be collapsed as close as possible to the solidification zone (frost line) so that the film is laid flat while still warm and flexible.

Downward extrusion into a cold-water (6-20 °C) cooling bath with outside or in/outside water cooling is also possible. In this case, line speed up to 150 m/min is feasible. Typical thickness of blown film made from Ultramid® is 20 to 180 μm.

Cast film is mainly extruded from Ultramid® B grades. It is normally drawn to a thickness of 20 to 200 μm (1 to 8 mils) from T- or coathanger dies of up to 2,000 mm (6.5 ft) wide. The die gap should be approx. 1.0-1.2 mm (multilayer film), line speed of 120 m/min is possible. For efficient production, extruders having screws of 60-150 mm (2.5-6.0 in) in diameter (25 to 28 D in length) are recommended.

Film properties and quality (i.e. tolerances, dimensional stability, machinability and transparency as well as thermoformability), are highly determined by the processing conditions. The chill-roll temperature should be set to 20- 40 °C for thermoforming film of high transparency or 80-120 °C for film of high dimensioned stability.