Petrochemicals

SYNCRATM HPIB

Refineries and petrochemical complexes with butene-rich C4 streams are well-positioned to enhance their value creation by producing high-purity isobutene for advanced downstream applications. The SYNCRATM HPIB technology offers a streamlined and scalable solution for achieving exceptional purity. This enables further integration into high-performance value chains targeting sectors such as automotive, construction, and pharmaceuticals.

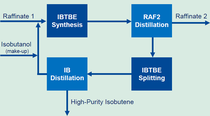

SYNCRATM HPIB features the etherification of isobutene using isobutanol to form isobutyl tert-butyl ether (IBTBE). This intermediate is then subjected to distillation and ether splitting, which separates high-purity isobutene from a mixture of n-butenes and butanes, called raffinate 2. While the resulting isobutene meets stringent purity specifications required for several downstream applications, raffinate 2 can be applied in the production of isooctene and, subsequently, isononanol, building on SYNCRATM IOC and SYNCRATM Oxo-C9.