Petrochemicals

SYNCRATM IOC

Refineries and petrochemical producers can maximize the value of their C4 streams by producing high-purity isooctene for fuel blending and chemical applications. The SYNCRATM IOC technology offers a flexible, robust and selective dimerization process, yielding premium C8 olefins suitable for high-performance downstream applications. As a key upstream component of the SYNCRATM Oxo-C9 technology, SYNCRATM IOC enables seamless integration into a broader licensing package—supporting the production of isononanol with excellent market perspectives.

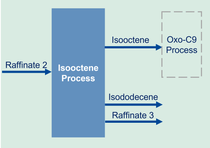

Isooctene production is based on butenes as raw material. These are usually sourced from butene-rich raffinate streams available from FCC (Fluidized Catalytic Cracking) units in refineries or from large-scale steam cracker operations in petrochemical complexes.

The SYNCRATM IOC process starts with the purification of the raffinate streams. The purified feed is then dimerized yielding a mixture of isooctene isomers, alongside minor quantities of isododecene and heavier olefins. Following dimerization, the product stream undergoes distillation to separate the desired C8 olefins from lighter and heavier fractions. The resulting isooctene achieves an exceptional purity and is highly reactive.

The IOC process is available as a standalone licensing option or integrated with SYNCRATM Oxo-C9, where isooctene serves as the feedstock for hydroformylation and hydrogenation to produce INA. This modular approach allows licensees to tailor their investment and product strategy according to market needs and feedstock availability.