Petrochemicals

SYNCRATM MAA

Methacrylic acid (MAA) is the precursor for a large variety of products, including methacrylates, coatings, adhesives and additives for several applications. BASF's unique SYNCRATM MAA process enables production via formaldehyde and ethylene-based propionaldehyde. This offers an excellent opportunity for the downstream integration of ethylene-based value chains, especially in combination with SYNCRATM Oxo-C3. Ethylene-based MAA production is associated with attractive economics and a reliable supply base.

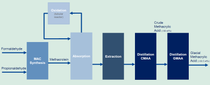

In the SYNCRATM MAA process, formaldeyhde (based on methanol) and propionaldehyde (based on ethylene) are first synthesized to form the intermediate methacrolein (MAC). Methacrolein is then further processed, including absorption, oxidation in a tubular reactor, extraction and distillation. The resulting crude methacrylic acid (CMAA, purity >98 wt%) is further distilled to give glacial methacrylic acid (GMAA) with a purity >99.5%wt, enabling usage in all relevant chemical applications.