Monomers

Life Cycle Assessment

Life Cycle Assessment on a mozzarella cheese packaging's entire life cycle

To better understand the environmental impacts of both the packaging format as well as the raw material source within a mozzarella packaging’s entire life cycle, BASF conducted a study with Südpack and Sphera.

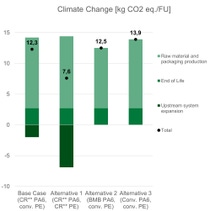

BASF’s sustainable mass-balanced polyamides Ultramid® Ccycled®, produced by using chemically recycled feedstock, or Ultramid® BMBcert, produced by using renewable feedstock, were examined in the mix with polyethylene.

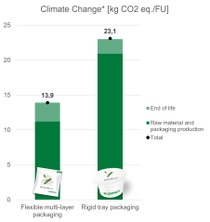

The results demonstrate that significantly lower environmental impacts, primarily resulting in a reduction of CO2 emissions, can be achieved by using flexible multi-layer packaging with a large share of chemically recycled or renewable raw materials.

LCA Study

Methodical Approach

LCIA methodology

Environmental Footprint (EF 3.0) assessment method published by the European Commission

Packaging Formats

Raw Materials

Base Case Chemically recycled* PA6 + conventional** PE

Alternative 1 Chemically recycled* PA6 + chemically recycled* PE

Alternative 2 Biomass-balanced* PA6 + conventional** PE

Alternative 3 Conventional** PA6+ conventional** PE

* via mass balance approach

** conventional = based on fossil raw materials; the pictures are illustrating the packaging format, in fact real supermarket-retailed mozzarella packagings were purchased, examined and used for this study.

Feel free to contact us!

Let’s discuss how we can support you in developing high-quality and sustainable solutions for your business.