Go Circular!

Monomers

Ultramid® Ccycled®

Reducing fossil resource consumption and product carbon footprint without compromising on quality and performance

Meet Ultramid® Ccycled®, our line for products using recycled raw materials instead of fossil raw materials.

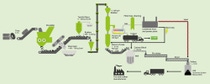

Since 2018, our ChemCycling® project deploys chemical recycling technologies turning plastic waste and end-of-life tires into a valuable raw material called pyrolysis oil. We use this pyrolysis oil at the beginning of the value chain, thereby replacing fossil resources.

Differentiate yourself from your competition by developing new products with Ultramid® Ccycled®!

Replace fossil with recycled feedstock: reduce fossil resource consumption by using recycled feedstock like pyrolysis oil instead of fossil raw materials in the production process.

Smaller product carbon footprint: Ultramid® Ccycled® products have a smaller product carbon footprint compared to conventional fossil-based products. The cradle-to-gate PCF is calculated according to Together for Sustainability methodology, accounting for a credit for the displaced incineration.

Virgin-quality output: Ultramid® Ccycled® products have the exact same properties as conventional materials without attributed recycled feedstock.

Drop-in solution: never change a running system! You can process our Ccycled® products in the same reliable way as our conventional products. You can use them in applications with high demands on quality, hygiene, and performance, be it in food packaging, yarns, compounds for automotive applications and many more.

Both the mass balance procedure, by which the proportion of recycled feedstock is attributed to the product, and the Ccycled® products themselves are certified by independent auditors, such as REDcert2 and ISCC PLUS. Furthermore, BASF SE is certified to RCS under alternative volume reconciliation, certified by Control Union (TE-00105122).

An LCA study conducted by Sphera for BASF, which was reviewed by three independent experts, finds that products manufactured with pyrolysis oil under a mass balance approach cause significantly lower CO2 emissions than those produced from primary fossil resources. The lower emissions result from avoiding the incineration of mixed plastic waste.

You can find all details about the available Ultramid® Ccycled® products on our customer portal:

Customer stories

Our Ultramid® Ccycled® product portfolio

We partner with a number of chemical recyclers who convert mixed plastic waste or end-of-life tires into pyrolysis oil. Based on the type of waste used, we can offer different Ccycled® products.

PostC = Post Consumer

Disclaimer: All claims subject to legal assessment by user.

An example for partnership

One of our strategic partners for the Ccycled® PostC2 products is Pyrum, a start-up from Germany. They have built pyrolysis plants which turns end-of-life tires into valuable resources such as recovered carbon black or pyrolysis oil. A special feature is that the by-product pyrolysis gas can be used to generate sufficient energy for the system to operate self-sufficiently.

Packaging & Extrusion

Textiles

Feel free to contact us!

Let’s discuss how we can support you in developing high-quality and sustainable solutions for your business.