Monomers

Ökobilanz

Lebenszyklusanalyse einer Mozzarella-Verpackung

Um ein besseres Verständnis über die Umwelteinflüsse sowohl von der Verpackungsart als auch der Rohmaterialquelle einer Mozzarella-Verpackung zu gewinnen, führte BASF in Zusammenarbeit mit Südpack und Sphera eine Studie zum Lebenszyklus der Verpackung durch.

Die massenbilanzierten Polyamide Ultramid® Ccycled® von BASF, die unter Einsatz chemisch recycelter Rohstoffe produziert werden, sowie Ultramid® BMBcert, welches basierend auf erneuerbaren Rohstoffen hergestellt wird, wurden in Kombination mit Polyethylen untersucht.

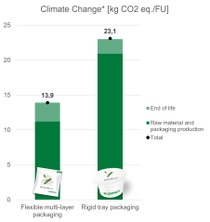

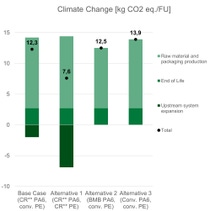

Die Ergebnisse zeigen, dass durch die Verwendung von flexiblen Mehrschichtverpackungen, die chemisch recycelte oder erneuerbare Rohstoffe nutzen, die Umwelteinflüsse signifikant verringert werden. Dies resultiert primär in reduzierten CO2 Emissionen.

Lebenszyklusanalyse

Methodischer Ansatz

Lebenszyklus-Wirkungsanalyse

Bewertungsmethode für den ökologischen Fußabdruck (EF 3.0), veröffentlicht von der Europäischen Kommission.

Verpackungstypen

Rohmaterialien

Base Case chemisch recyceltes* PA6 + herkömmliches** PE

Alternative 1 chemisch recyceltes* PA6 + chemisch recyceltes* PE

Alternative 2 biomassen-bilanziertes* PA 6 + herkömmliches** PE

Alternative 3 herkömmliches** PA6 + herkömmliches** PE

*durch Massenbilanzansatz

**herkömmlich: basierend auf fossilen Rohstoffen; die Bilder illustrieren lediglich das Verpackungsformat; tatsächlich wurden in Supermärkten vertriebene Verkaufsverpackungen erworben, wissenschaftlich hinsichtlich Ihrer Zusammensetzung untersucht und für die Studie herangezogen.

Kontaktieren Sie uns gerne

Lassen Sie uns gemeinsam diskutieren, wie wir Sie bei der Entwicklung von qualitativ hochwertigen und nachhaltigen Lösungen unterstützen können.