Monomers

B2Last® - Plant modification and technical Support

In order for B2Last to be used in the asphalt mixing plant, it must be homogeneously introduced into the bitumen as a low-viscosity liquid. This may require small adjustments to be made to the plant construction. We support our customers in individual analyses of their plants, in creating retrofitting concepts and in performing plant experiments. We are in close contact with our experienced plant constructors to provide this support, please contact us for more information.

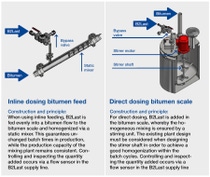

Homogenization with the fresh binding agent prior to the asphalt mixing process is important to ensure the performance of B2Last®. Two techniques have become established for feeding and mixing of B2Last, however, other methods of producing bitumen containing additives are conceivable. We will gladly offer you an individual on-site tour of the mixing plant.

B2Last modifies the bitumen for every mixture batch individually in a discontinuous process. Pump conveying capacities of up to 60 l/min are typical for achieving feed quantities of between 1% and 3% B2Last in relation to the total quantity of the binding agent. The required dosing performance depends on the batch size, bitumen conveying capacity and process control at the mixing plant.

Application examples for dosing and mixing of B2Last in bitumen at the mixing plant

The use of B2Last has already been implemented at various mixing plants. The implementation introduced here is based on feeding in the bitumen scale, a process with which individually modified mixture batches can be produced. The additive is stored in a weather-protected area which is equipped with a safety trough. B2Last is conveyed to the supply terminal via a gear pump and dosed in the bitumen scale. The process can be controlled via the mixing plant’s control room.