Properties of thermoplastic polyamide

- Material strength

- Low material usage

- Smoke/water permeability

- Not edible

- Good peeling behavior

Monomers

The unique combination of strength and water permeability makes Ultramid® H an innovative material for e.g. artificial casings in which sausages can be smoked and then dried.

Such casings have so far been made of collagen or cellulose, for instance. As the new polyamide can be used to produce artificial casings with significantly thinner walls due to its strength, it is an attractive alternative to these materials. Thanks to the hydrophilic properties of Ultramid® H, the desired smoke aromas pass through the artificial casing made of pure polyamide into the sausage products during the smoking process. The high water permeability allows subsequent drying directly in the casing.

Ultramid® H opens up new fields of application for thermoplastic polyamides that were previously beyond technical capabilities and is unique among thermoplastics. It can be processed like any other polyamide, enabling our customers to incorporate Ultramid® H into their production processes without making any adjustments.

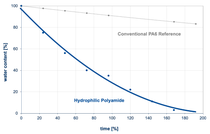

The graph shows the comparison of time required for evaporation of water from sealed artificial casings. Ultramid® H shows superior water permeation properties compared to conventional PA6. This is a significant advantage in the drying or smoking process of e.g. sausages.