We support you to achieve your sustainability goals with our low carbon ammonia products.

Monomers

Ammonia based chemicals

Portfolio

Ammonia

Ammonia production plant in Ludwigshafen

Ammonia is one of the world's most produced chemicals with an annual global capacity of 235 million metric tons. BASF's invention of the ammonia process in 1913 laid the foundation for this success story. Industrial ammonia is the starting point of modern agriculture as well as many petrochemical value chains. The colorless substance is gaseous at room temperature and has a characteristic pungent odor, so strong that humans can detect even the slightest concentrations of it.

The main application for ammonia at BASF is urea, which can be produced from ammonia and carbon dioxide at high pressures. Still, ammonia is an important raw material for many other value chains such as nitric acid, amines and isocyanates.

BASF sells ammonia anhydrous via pipeline, barges and in railcars. BASF also sells ammonia solution 24,5% in railcars and tank trucks.

Urea

Prill tower – part of the urea plant

BASF developed the world's first industrial urea production more than 100 years ago. Today, urea is one of the most important raw materials in the chemical industry. It is used in a wide variety of production processes and produced at the Ludwigshafen site since 1922.

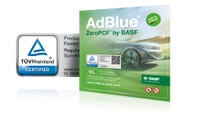

Urea can be used in many different ways. For example, it is used in the production of glues, impregnating resins and fertilizers, but is also used as an ingredient in certain cosmetic products and medicines. It is also used to produce AdBlue®, the additive for diesel engines.

Typical customer industries are the cosmetics and pharmaceutical industries, as well as producers of urea solutions. BASF sells urea prills in big bags or bulk as well as urea solution in bulk.

Liquid CO2

Liquid CO2

In Ludwigshafen, BASF liquifies part of the CO2 generated during the ammonia production process. Carbon dioxide is incombustible, colorless and odorless.

BASF's customers use carbon dioxide for the production of beverages, in comminuting, metering, dispensing and packaging of food, for extraction purposes, to isolate or remove flavorings from natural materials and for the production of dry-ice and pellets.

BASF sells liquid CO2 (LCO2 3.0) in trucks and railcars.

BASF now offering products with reduced product carbon footprints for its ammonia and urea portfolio grades.

Ammonia production at BASF

For more than 100 years, ammonia has been an indispensable part of the production Verbund. BASF has a global capacity of ammonia of 1.4 million metric tons.

The beginning

In September 1913, the first industrial-scale ammonia production plant came on stream at BASF in Ludwigshafen. Ammonia synthesis was only made possible by the Haber-Bosch process.

The optimization for ressource efficiency starts

In 1922, BASF built the world‘s first urea plant in Ludwigshafen. Urea was initially used for nitrogen fertilization, but soon also for the production of wood glue.

Expansion of a successful technology

In the late 1960s, the melamine and the CO2 liquefaction plants were built. The portfolio was expanded in 2004, when BASF started its AdBlue® production in Ludwigshafen. AdBlue® is a trademark licensed globally by the German Automotive Association (VDA) for an aqueous solution made up of 32.5 % urea and demineralized water.

2015 – A landmark agreement

The Paris Climate Agreement is an international accord that was adopted by nearly every nation in 2015 to address climate change and its negative impacts. The agreement aims to substantially reduce global greenhouse gas emissions.

In 2021 BASF presented its roadmap to climate neutrality