Monomers

Polyamides and Precursors

At BASF, we are one of the leading producers of polyamides and precursors used for various applications ranging from packaging and textiles to films and engineering plastics.

Commonly known under the brand name Ultramid®, we offer PA66 grades (Ultramid® A), PA6 grades (Ultramid® B), PA6/66 co-polymer grades (Ultramid® C) and the respective precursors.

We have a global footprint with production sites in Ludwigshafen and Freiburg (Germany), Chalampé (France), Antwerp (Belgium), Freeport (USA) and Shanghai (China).

As part of the Monomers division, we market polyamide for fiber and extrusion applications. Our polyamide compound portfolio is developed and marketed by BASF's division Performance Materials.

Our latest news releases

Sustainable solutions

Besides our standard products, we offer a broad portfolio of more sustainable solutions. Let’s find out which one fits your needs best in reducing fossil feedstock and CO2 emissions.

Choose your more sustainable polyamid solution:

Product Carbon Footprint (PCF)

How our products can reduce your carbon footprint

How much greenhouse gas (GHG) emissions are associated with a product along its life cycle? This question becomes increasingly important with more and more companies…

Packaging, films, and monofilaments

Extrusion

Our medium to high viscosity Ultramid® grades are the perfect choice for demanding applications in packaging, films, and monofilaments. Our Ultramid® extrusion grades provide exceptional strength and thermoformability, high heat resistance and very good barrier properties to gases, flavors, and aromas.

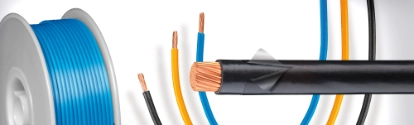

Applications

Ultramid® extrusion grades are offered in a wide variety of combinations of viscosity and additives. Their outstanding properties have made them indispensable for transparent and flexible food packaging, medical packaging, monofilament applications (e.g. fishing lines, fishing nets, lawn trimmers) and cable sheathing.

Product Range

Nomenclature

Fibers

Polyamides for fibers

Our low viscosity Ultramid® grades are the perfect choice for demanding applications in yarns and filaments. Our Ultramid® fiber grades provide strength, durability, exceptional softness and wearing comfort for carpet, textile, or technical yarns.

Applications

Yarns made from Ultramid® spinning polymers are the basis for clothing, sportswear, floor coverings, industrial yarns etc. With the different grades in the Ultramid® range, we are able to meet these special requirements.

This polymer is like no other. Tight tolerances in viscosity and amino end groups, together with excellent melt stability, guarantee optimum homogeneous spinning and are the basis for even dyeing and problem-free texturing. Ultramid® supports a smooth, consistent spinning process.

Precursors

Polyamide precursors

Besides our Ultramid® polymer products, we offer a range of related precursors, for example caprolactam, hydroxylammonium sulfate, AH-salt, hexamethylene diamine and adipic acid.

Products